fuel pellet mill

Fuel pellet mill is used to make fuel pellets from biomass raw materials as sawdust, wood shaving, wood chip, rice husk, cotton stalk, grass, straw, bagasse, coconut shell, etc. It can make the loose raw materials into dense solid pellets fuel to replace coal or petrol. It can on one hand save energy, on the other hand reduce greenhouse gas emission, which is both economically and socially beneficial.Ring die fuel pellet mill has many advantages:

- It produces clean and environmental friendly bio fuel, so fuel pellet mill can be called GREEN MACHINERY.

- It adopts automatic electronic control grease adding system, so that the machine does not need to stop for lubrication.

- The ring die is made from high quality stainless steel, which is more wear-resisting. Both ring die and roller are processed by carburizing heat treatment, while the carburized layer can be as deep as 2mm, which makes their wear-resistance more than a dozen times than common heat treatment. The pellet mill die holes are processed by advanced drilling machine, so that the compression ratio of ring die is more accurate, and pellets shape more beautiful.

- Its roller lubricating part applies world leading air cooling and dedusting system, which makes the air to blow inside pelletizing chamber, so as to efficiently decrease the temperature in pelleting chamber. At the same time, this system also recycles the dust and powder material for reproduction, so that it saves production cost, which is an innovation in biomass pellet making field.

Industrial fuel pellet mill composition

- Machine frame; 2. Feeding inlet; 3. Pelletizing chamber; 4. Reduction gear box; 5. Electric motor; 6. Main shaft; 7. Driving device; 8. Outlet.

How does it work?

When the biomass waste like sawdust is fed into the pelletizing chamber, it is stirred and compressed by the dual function of the autorotation of the main shaft and roller. The pressed sawdust is then extruded from die holes over the pressing of roller. Then the dense pellets are cut outside the ring die, and 5cm long (around) pellets fall from the outlet and collected.Fuel pellet mill has wide applications

- Make fuel for civil heating and household energy consumption: pellets fuel have high burning efficiency and are easy for storage.

- Industrial biofuel boiler: as the main fuel source for industrial boiler, pellets can replace coal to solve environment pollution problems. The fuel pellet mill can make sawdust, shaving, waste wood pieces and bagasse into dense pellets for boiler with high efficiency and are clean. Fuel pellet mill can also make pellets from the household refuse, so it also makes contribution to environmental protection.

- Make fuel for thermal power generation plant. Biomass pellets are good source of fuel for power plants.

If you're interested in our products or have any questions, please do not hesitate to contact us!

Products

- wood pellet mill

- rice straw pellet mill

- rice husk pellet mill

- peanut shell pellet mill

- waste paper pellet mill

- switch grass pellet mill

- corn stover pellet mill

- wheat straw pellet mill

- straw pellets machine

- sawdust pellet mill

- bagasse pellet mill

- pellet packing machine

- drying machine

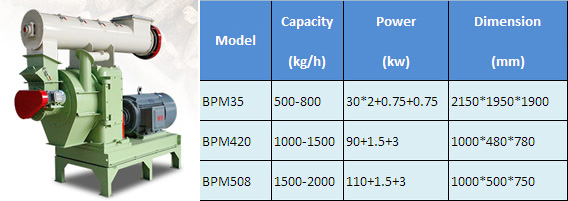

- hammer mill

- coconut shell pellet mill

- bamboo pellet mill

- grass pellet mill

- alfalfa pellet mill

Contact Us

Anyang Gemco Energy Machinery Co., Ltd.(office)

Add: 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, P.R.C.

Zip Code: 455000

E-mail:info@biopelletmill.com

Tel: (86) 372 5965148

Fax: (86) 372 5951936

Add: 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, P.R.C.

Zip Code: 455000

E-mail:info@biopelletmill.com

Tel: (86) 372 5965148

Fax: (86) 372 5951936