bio fuel pellet line makes waste into wealth

Bio fuel pellet line means the production line that makes fuel pellets from biomass. The biomass for producing fuel pellets can be wood, sawdust, bamboo, coconut shell, EFB/palm fiber, stalk, alfalfa, hops, etc.(more raw material see Products.)

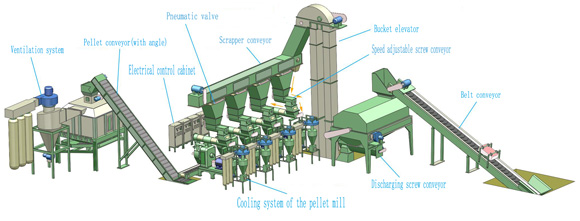

The bio fuel pellet production line is divided into around 8 procedures:

Crushing, raw material conveying, drying, pellet production, sieving, cooling, pellet conveying, packing and storage. Below is the detailed process

Bio fuel pellet line process

- Crushing: wood chipper, crusher or hammer mill.

No matter your raw material is wood, straw, grass or anything else, the first step of bio fuel pellet production line is to crush them into regular small size. Generally the size must be smaller than the pellet size. For example, if you want to produce 6mm pellets, the raw material must be crushed into <6mm.

The wood chipper is used to chip the large size wood into smaller size to be suitable to put into crusher.

The crusher/hammer mill is used to crush raw material with small than 1 inch into final size.

|

|

| Wood chipper | Hammer mill |

- Raw material conveying: fan, cyclone separator, screw conveyor

- Drying: rotary drum dryer or air flow dryer

The biomass raw material usually contains too much moisture, which is not suitable for direct pellet production. As a result, dryer is needed.

The rotary drum dryer is used for medium to large scale bio fuel pellet line (>500kg/h), while air flow dryer is for small to medium scale bio fuel pellet line (200-700kg/h).

After drying, the biomass moisture content is decreased to around 10%-20% based on different raw materials.

- Bio fuel Pellet production: flat die or ring die pellet mill

Flat die pellet mill can produce 50-800kg/h, while ring die pellet mill can produce 500-2000kg/h.

|

Flat die pellet mill is easy to clean, and its roller and die are easy and fast to change. It has compact structure and more flexable to use. |

Ring die pellet mill is more suitable for processing wood raw material, and the pellets made by ring die pellet mills have higher quality and suitable for sale. |

|

|

The pellet mill die hole is determined by the pellet size you want to produce and the raw material characteristics.

-

Sieving and cooling:

Sieving and cooling:

After processed by the pellet mill, some raw material may remain powder because of the insufficient pressure inside pellet mill or binder is not enough. In this case, the pellets shall be sieved, and the powder can fall down from the sieve, while pellets stay on the sieve. Usually the sieve is vibrating, so that pellets can gradually fall to the pellet conveyor.

And the pellets made by the pellet mill often have high temperature and shall be cooled.

At GEMCO, we have a pellet cooler that can sieve the pellets at the same time. This kind of pellet cooler can save energy and production area, so it is very effective.

- Pellet conveying: belt elevator

- Pellet packing and storage: pellet packing machine, bags.

Besides the above discussed procedures, there are actually some other steps needed for the complete bio fuel pellet line based on customer requirement. If you are intending to set up one, just feel free to contact us for free plans!

- wood pellet mill

- rice straw pellet mill

- rice husk pellet mill

- peanut shell pellet mill

- waste paper pellet mill

- switch grass pellet mill

- corn stover pellet mill

- wheat straw pellet mill

- straw pellets machine

- sawdust pellet mill

- bagasse pellet mill

- pellet packing machine

- drying machine

- hammer mill

- coconut shell pellet mill

- bamboo pellet mill

- grass pellet mill

- alfalfa pellet mill

Add: 19F, Suite B, Global Trade Mansion, Wenfeng Avenue, Anyang, Henan, P.R.C.

Zip Code: 455000

E-mail:info@biopelletmill.com

Tel: (86) 372 5965148

Fax: (86) 372 5951936